Production

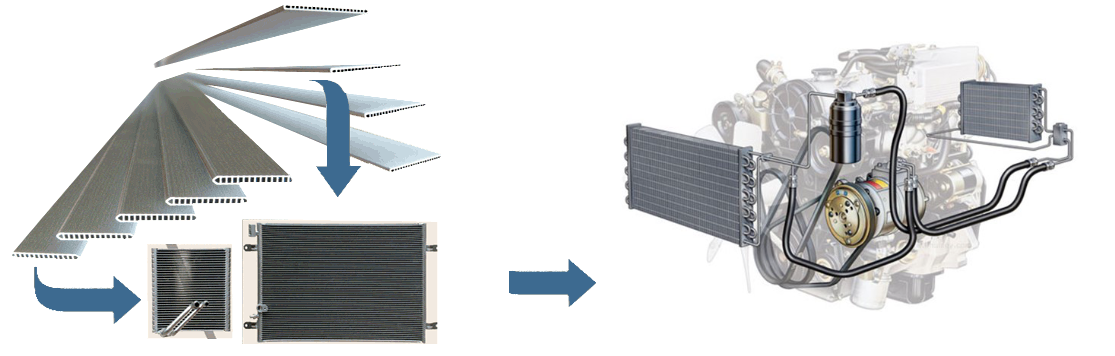

Manufacturing process of micro-chanell profiles for heat-exchangers consists of three main fully automated proces coming out of long term development and knowledge of our mother company.

- In the first process, aluminium billets are extruded to almost final shape of micro-chanell profile with small holes through which the refrigerant flows.

- In the second step this profile is coated by a special coating to serve as a brazing agent during heat-exchanger manufacturing by our customer. As an option some of our profles can be supplied without coated layer.

- In the latest step tubes are sized and cut to final dimensions, packed and shipped to the customer. Again as an option we can deliver profiles coiled on spooles or just winded without spool. In that case the cut-to-length step is realized at a customer production line.

- All processes, as well as incoming material and final products, go through the strict inspection to ensure the highest product quality and the customer´s satisfaction.